Toolbox for Change

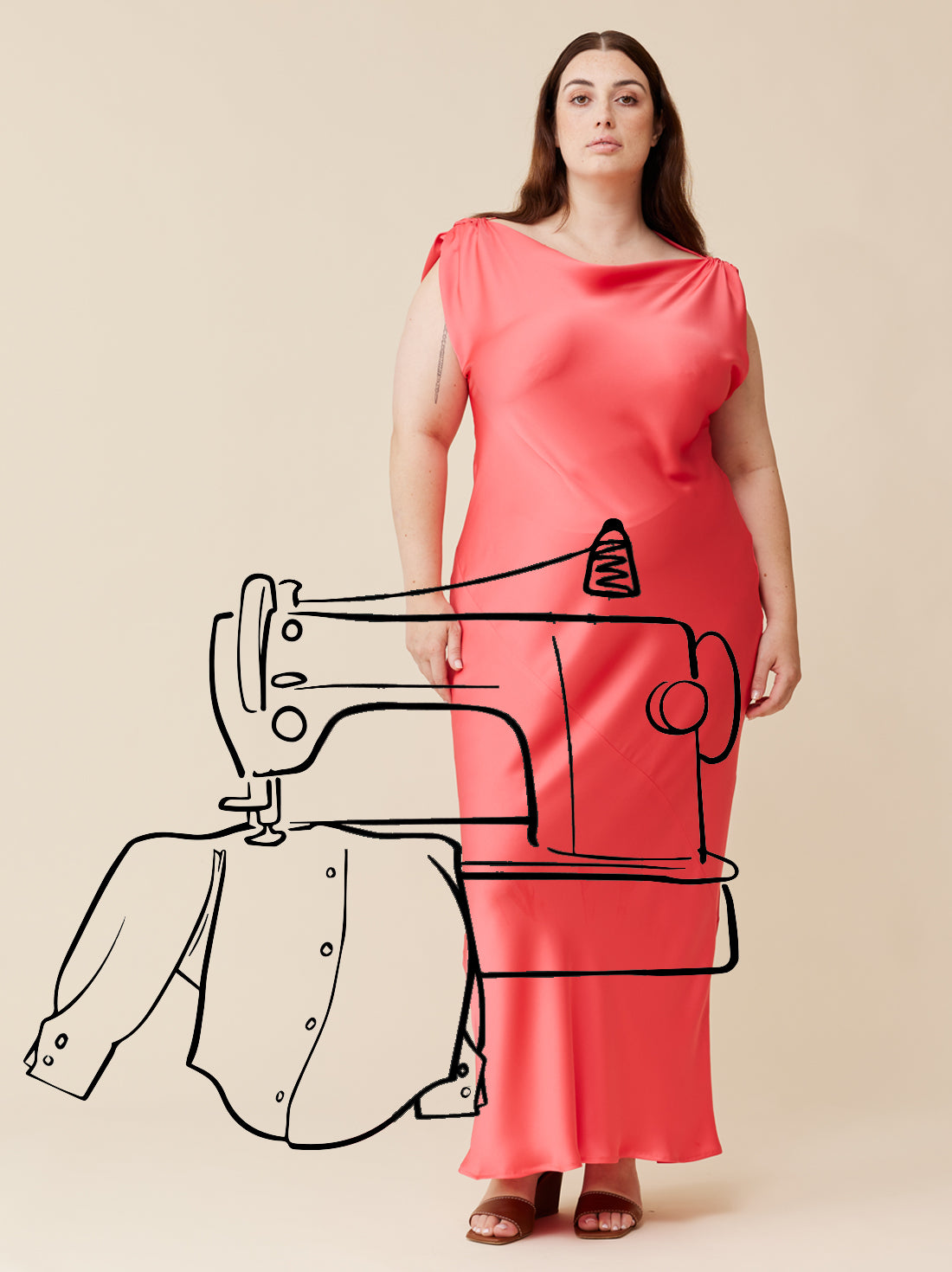

Rubettes,

Clothing is valuable! It is a crucial part of our everyday lives. It shapes our individual experiences. It reflects and contributes to our culture.

I start with this because it is important that we lovingly hold this reality front and centre while we also acknowledge the deep flaws in the clothing industry. It is only by acknowledging the true value, and the true joy, of clothing that we can meaningfully address the industry’s problems, and step into the unknown together to solve them.

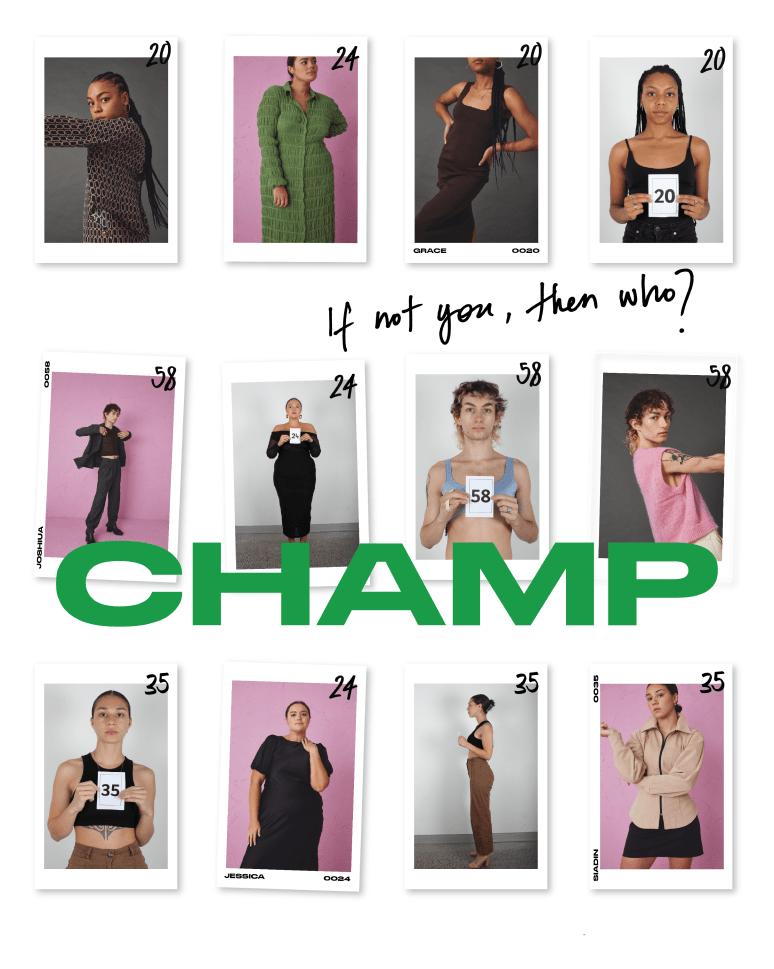

From the farming, extraction or recycling of raw materials, to the decisions about sizing, who clips the threads on a freshly-made shirt, and who that shirt is photographed on, the clothing supply chain is extremely complex and at times opaque, even to us.

I have had to accept that trying to solve every single problem in that supply chain is a fool's errand. The clothing industry's issues are so large and global, that not one company can fix everything. This is what makes collaboration and transparency so crucial. It also means that we have had to work out the areas of the industry we will lead change, and the areas where we will follow someone else’s lead.

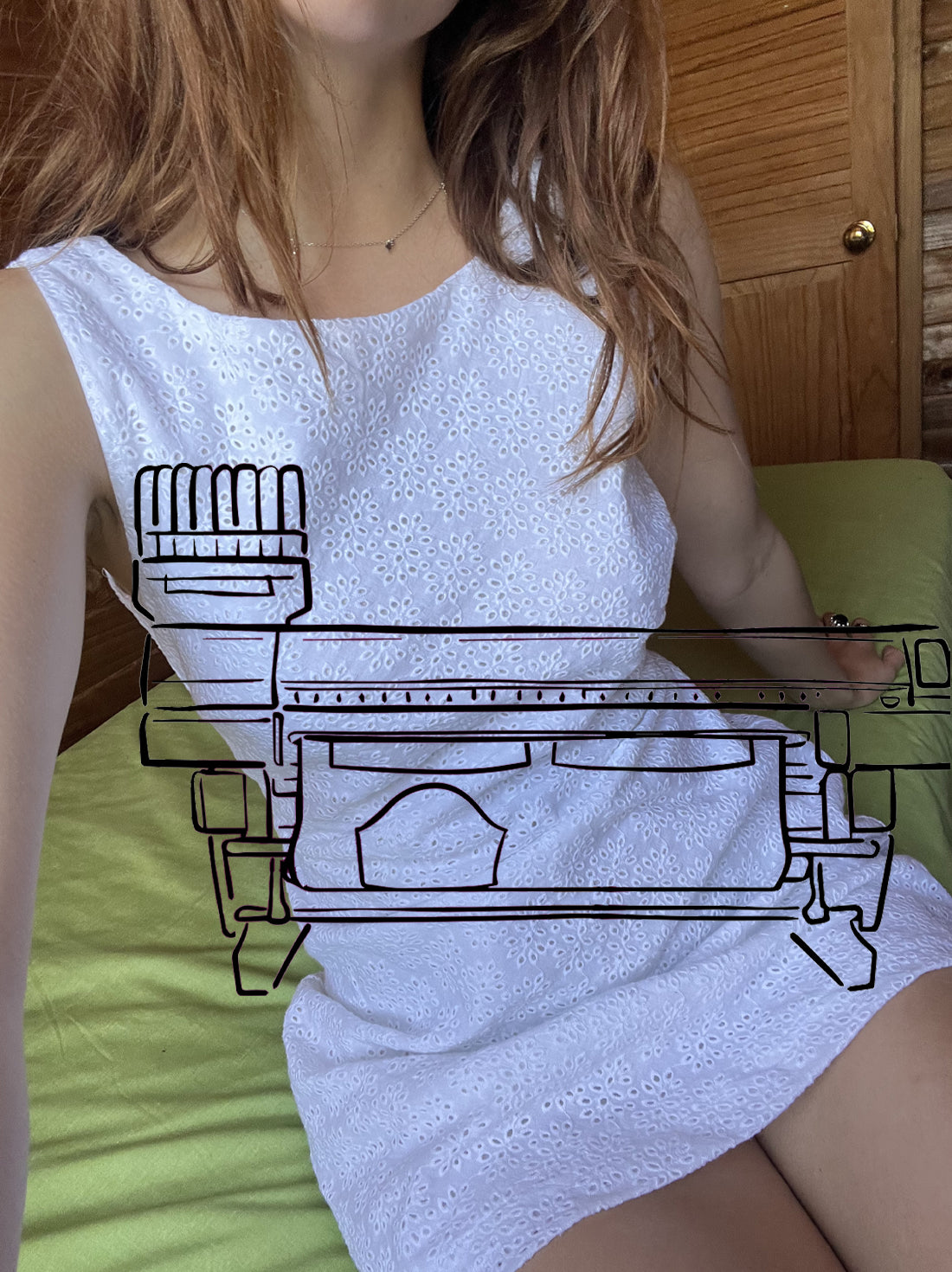

When I think about how we at RUBY can help solve problems, the Toolbox is a useful analogy. There are the standard tools: tools that everyone should really have. Use of

Better Practice materials,

responsible manufacturing processes,

carbon reduction plans

,

these are the non-negotiables of doing business. In these areas, we can learn from each other on the best decisions to make, or how to channel our energies so that we have the most positive impact. I am grateful for the openness of fellow designers about their work in these areas. Most of all I am grateful to

Mindful Fashion, and Programme Director Jacinta FitzGerald’s ability to synthesise complex information and guide us on how to use it.

Also in our Toolbox is equipment that we have really saved up for. Specialist tools that we are learning how to wield, and how to share with our community.

For us, this is the

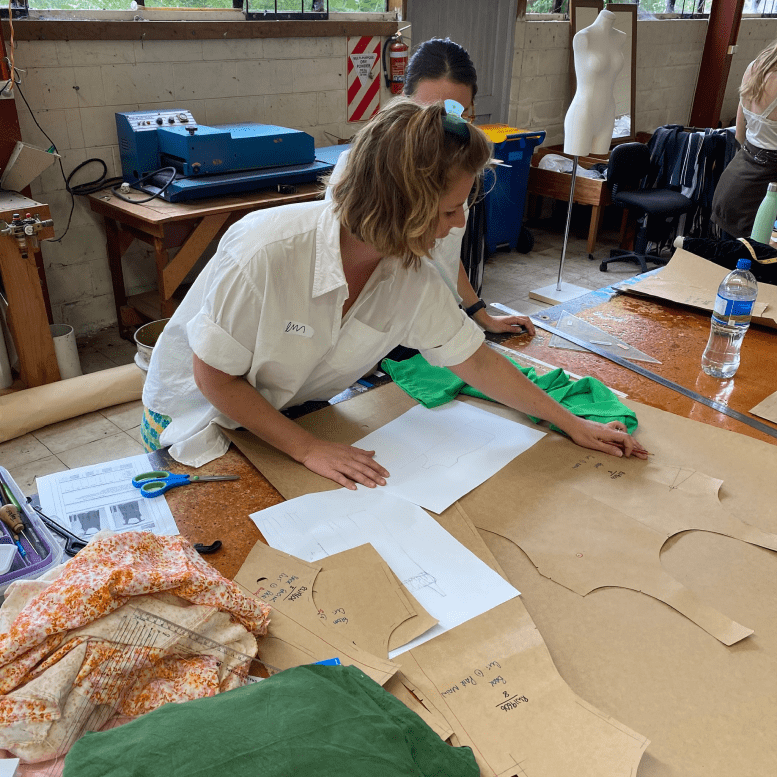

work we have done on waste minimisation

,

and how we nurture a

mutually nourishing relationship with our community.

Nothing is, or will be complete. We will never arrive at a place where we are done. We continue to strive, learn and adapt.

And in a similar vein, if you’re searching for “the most sustainable product”, you won’t find it. There is no silver bullet, just choices that are better than others. Okay, and now on to the topic of communication. Let’s have a lil’ chat about greenwashing. An increasing number of companies and customers are rightly focusing their energies on the impacts of their production or consumption choices, leading to an increase in communications about sustainability. Some of these claims are authentic, and some are not.

We have been in conversation with the Commerce Commision in New Zealand as part of an industry notification for the clothing industry, particularly around sustainability claims. It is our job to ensure what we tell you is accurate, and these conversations have been a useful resource for us to guide the creation of this, our new and improved Toolbox section of our website.

Essentially, it is a breach of the Fair Trading Act for us to make specific claims that we can not back up. We could also be in breach if we make an aspirational claim (for example, “aiming to be Carbon Positive by 2024) without being able to provide evidence of how we are reasonably going to get there.

Most of our evidence (for example certifications, or internal planning documentation on projects) we have not published, essentially because we are trying to ensure this section isn’t overwhelming. In the case of certifications specifically, some of our pieces are made from certified material, but the company that makes the garments does not hold that same certification, so therefore we can’t publish it. We go into more detail on this in the Materials section of this Toolbox. But please know that you are able to contact us to request it should you want more information.

Lastly on communication, you may notice that sometimes our language might seem more like a “Chatty Cathy” is writing to you rather than a company that is seriously committed to minimising its impacts. The thing is, you can think critically and have fun at the same time. And it’s important that we do have fun while doing this work, which can at times feel enormous and overwhelming.

Same goes for our 5 icons that we use to tag certain garments. I think they look cute. At first I was worried that we were making them TOO cute, and it would take away from the importance of them. In the end, cute won.

![]()

![]()

Sustainability is something that is discussed at all levels of the business - from our part time Sales Assistants to our Board of Directors: we need our whole team to be onboard to ensure the success of our goals. I want to acknowledge and thank everyone, at all levels of the company, as well as our external sustainability consultants for the energy they put into this.

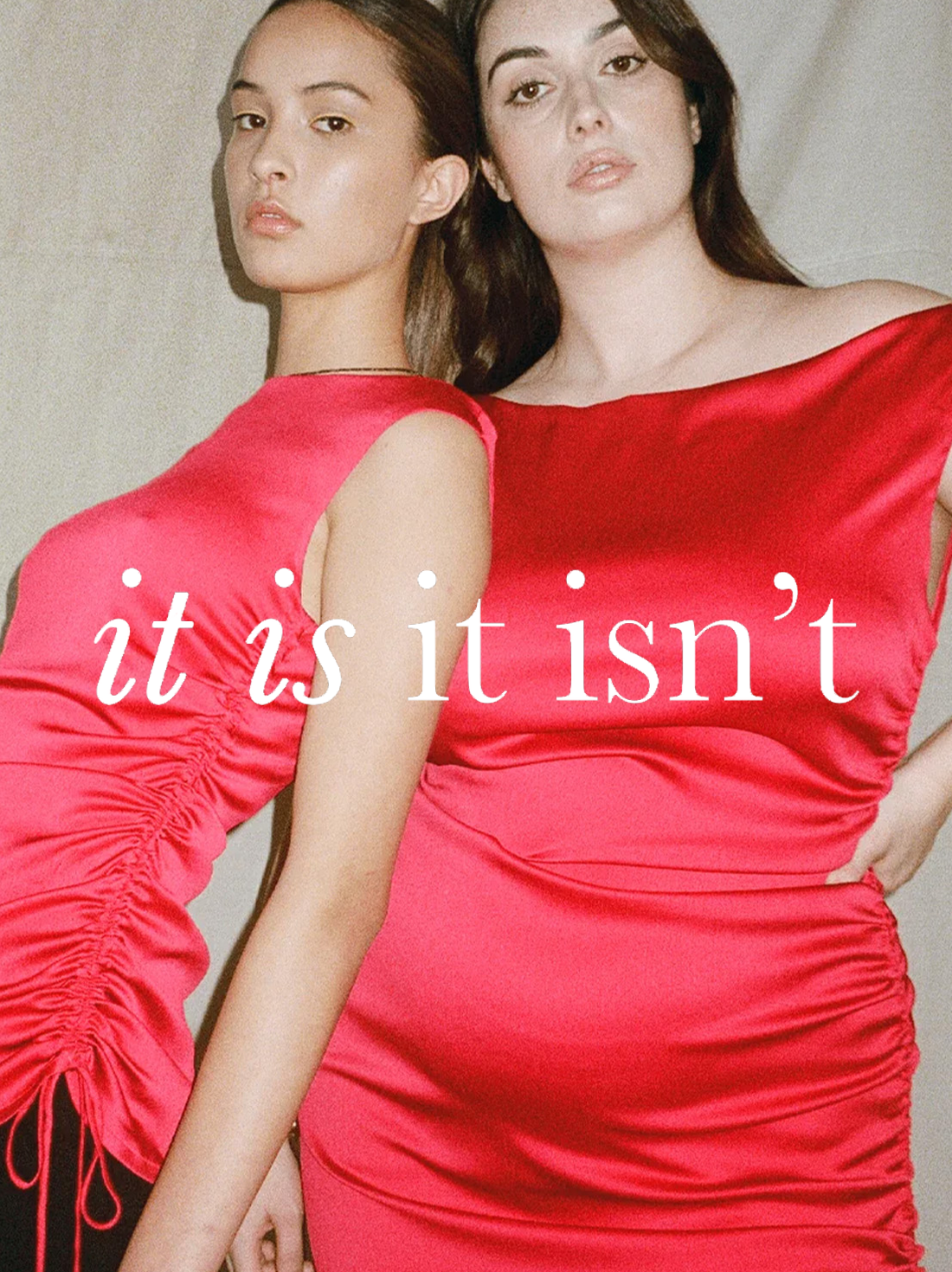

In order for true progress to be made, the knowledge that we gain in our explorations cannot be kept just for us. It has to be shared. It is my hope that through openness and collaboration, what we have learned can be picked up by other companies, and used in a way that makes sense for them.

Maybe what I am saying resonates with you, maybe it doesn’t. Regardless, I really welcome your thoughts - you might be a loyal Rubette, someone who has just stumbled upon us online, from a non profit, a supplier, or a fellow designer. The only way we can truly make meaningful change is by learning from each other, and genuinely working together.

x Em

RUBY General Manager